Arrow is one of the oldest and most recognized brands in the engine spares aftermarket, producing over 10 million parts annually.

This is possible through our MACHINING division and vast network of affiliations and associations. We purchase goods in raw/semi finished stages and bring them to our machining unit. Our In-house machining facility is equipped with high-end CNCs, VMCs and SPMs to supply precision machined components. The state-of-the-art quality control lab is up-to date with inspection and testing tools and equipment. Thus ensuring that every piece you receive from us is “PERFECT”.

At Arrow we live by the mantra “Quality, Perfection & Innovation”.

Arrow Connecting Rods are drop forged from 42CrMo4 steel. They are normalized, quenched and tempered. We also make Connecting Rods of C-70 grade with a hardness of 262-302 BHN. All rods are checked 100 percent for Cracks, Machining and Forging Defects. We use 10.9 grade bolts and nuts for tractor Connecting Rods and 12.9 grade bolts and nuts for automobiles and trucks. The Big End bores of all Connecting Rods are honed and mirror finished.

Our Quality Check for these connecting rods consists of checking the center-to-center distance, straightness, parallelism, alignment, ovality, twist and bend. We also produce Connecting Rods by Fracture Splitting Technology.

We offer a full design, development and manufacture service for crankshafts machined from solid steel billet or forged material. We offer crankshafts in standard or custom specifications which are precision machined, lighter in weight and come with superior inherent dampening features. Crankshafts are meticulously tested on various quality parameters to maintain high quality.

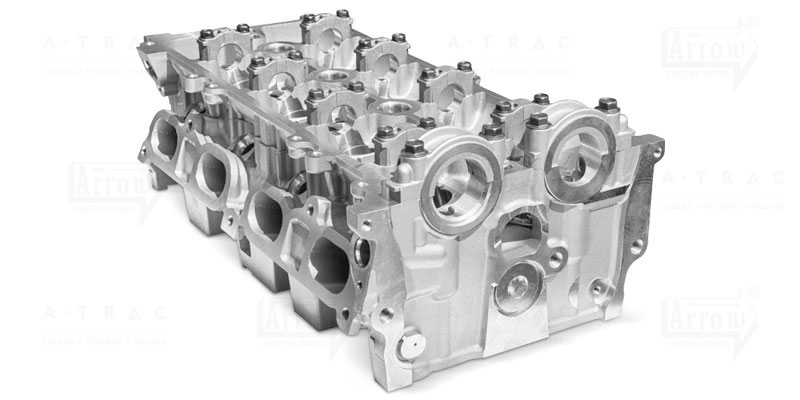

Cylinder Heads are produced mainly in cast iron. They are manufactured using shell moulding casting process to achieve a uniform wall thickness of the water jacket. All Cylinder Heads are machined using highly advanced CNC Machines for superior dimensional accuracy. The casting and the water passages are cleaned using the shot blasting process. Various types of testing are done to ensure defect free product. Atrac can also offer aluminum cylinder heads as per customer specifications.

Piston rings are individually cast and close material control ensures high tensile strength, resistance to wear and scuffing and to collapse at operating temperatures. Each Ring is double turned, barrel honed and ground to maximum accuracy for smoother performance and low fuel consumption.

In consideration of the demanding needs for a bearing surface. ARROW engine bearings are available in four materials.

Bushes are made by us of 4 kinds.

Bi-metal Bushes the most popular being steel back with copper lead alloy lining. This is specially used for high loads.

Hard Bronze having 90% copper and 10% Tin are used for several working conditions and heavy pressures specially for applications like connecting rod bushes and valve guides.

Red brass bushes having 85%copper, 5% Tin, 5% Lead and 5% Zinc are generally used for water pump impellers and slow speed engines.

Aluminum bushes Aluminum bushes are with properties such as high load carrying capacity, fatigue, strength and thermal conductivity, in addition to excellent corrosion resistance and low cost.

Our high chrome alloy and PL-12MV valve seat inserts are best suited for use in light alloy and cast iron cylinder heads as they offer good wear resistance at high temperature and high corrosive resistance.

Valve Guides are made from two kinds of materials

• Grey Cast Iron

• CuZnAI-alloy

GREY CAST IRON of perlitic structure with high phosphorous content. The perlitic structure and the reticular phosphide distribution along with the good graphite formation give high wear resistance and improved running properties in poor lubrication condition.

CuZnAI- alloy guides have excellent wear resistance and low coefficient of friction. Used for highest stressed guides. All our Cast Iron Guides are manufactured having minimum hardness of 95 HRB (210 BHN).

Atrac offers an extensive range of Gaskets that are highly durable and have the capacity to withstand high loads. Available in different sizes, these cylinder head gasket can be customized as per the specification of the customers. These gaskets are manufactured in various materials like Copper, Steel, and Beater etc. and are available in asbestos as well as non-asbestos materials. The offered gaskets are covered with silicon sealer and silicon non-stick coatings that offer flawless performance.

We offer our customers a broad range of aftermarket Oil Pumps for different engine applications and needs. These pumps are remarkable for their efficiency and extended service-life besides meshing perfectly with existing systems. Our Oil Pumps are optimized to lower the overall emissions of combustion engines.

Atrac offers automotive water pumps manufactured in compliance with the requirements of our clients using high-grade raw material. Our water pumps are highly durable, anti-corrosive, leak proof and have high tensile strength. Moreover, we supply water pumps in different sizes and dimensions that help in meeting the diverse requirements of our clients.