A piston ring’s function and usability determine how it is manufactured and classified. Piston rings were designed to seal chambers (where pistons move), which include combustion chambers in 2-stroke and 4-stroke engines. There are at least three rings fitted around a marine engine’s piston.

Depending on the type and capacity of the engine, the piston ring has different numbers and functions.

This article will explore piston rings’ types, importance, and functions.

What Is Piston Ring?

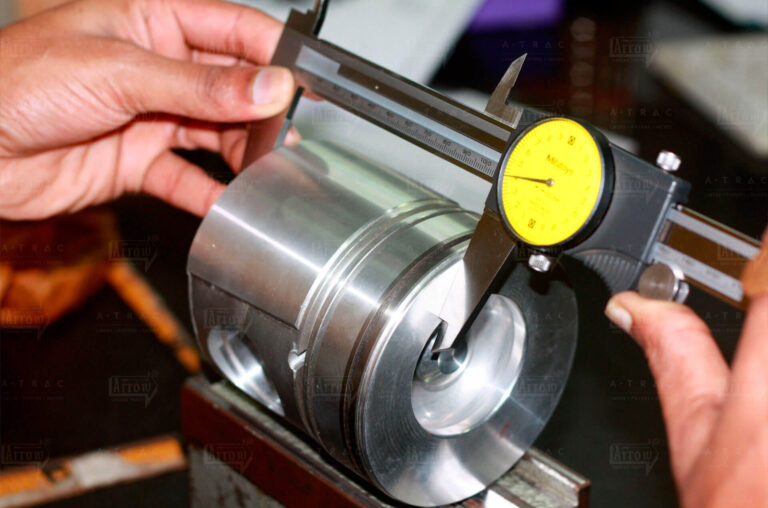

A piston ring in internal combustion or steam engine is a metallic ring encircled and attached to the outer diameter of the piston.

Essentially, piston rings seal the gap between the piston and the cylinder wall, preventing the entry of pressurized combustion gases into the oil sump. The oil pumps also act as a regulatory mechanism to prevent excessive amounts of oil from entering the combustion chamber and being burned. Rings must be in good working order for a proper engine to function at maximum efficiency and power.

Why Are Piston Rings Important?

Piston rings are one of the main components that form a gap between the piston and the cylinder wall. In the case of a minimal gap, the piston could seize in its cylinder through thermal expansion, leading to serious damage to the engine.

An excessive gap, however, would result in insufficient sealing between the piston rings and the cylinder walls, increasing blow-by (combustion gas entering the crankcase) and decreasing pressure on the cylinder, thus reducing engine power.

Engine friction losses are caused by the piston ring sliding within the cylinder wall. It has been estimated that nearly 24% of the total mechanical friction losses for the engine come from friction caused by piston rings. Thus, piston rings have been designed in a way that minimizes friction yet achieves good sealing and an acceptable life expectancy at the same time.

Since piston rings have to be lubricated with oil, the quality of motor oil has been dramatically improved due to the difficulty of lubricating piston rings.

As the oil must survive high temperatures and harsh conditions to glide smoothly, it has to sustain high speeds.

It is challenging to lubricate the rings because of the oscillating motion of the rings instead of the continuous rotation of the bearing journals (as with a bearing).

When the piston movement is limited, the piston ring reverses direction and stops. As a result, the lubrication of a hydrodynamic bearing is no longer effective as it used to be due to the disruption of the oil wedge effect.

To maintain a tight closure, seal rings are provided with spring force either by their stiffness or by a spring behind them.

For rings to stay in contact with the cylinder, they must float freely inside the piston grooves. Engine failure is frequently caused by piston rings binding in the piston, a buildup of combustion products, or a breakdown of the lubricating oil.

Types of Piston Rings

A small engine commonly uses three types of piston rings:

Compression Rings or Pressure Rings

Compression rings seal above the piston, preventing the combustion side from leaking gas. These rings are positioned in the first groove of the piston.

According to the engine’s design, this may vary. These rings serve the dual purpose of sealing combustion gases and transferring heat from the piston walls to the piston.

A layer of oil left by the oil ring is sheared, providing sufficient lubrication for the top compression rings. Additionally, it aids in sealing and heat transfer with the top compression ring.

Wiper Rings

Napier rings, also known as wiper rings or backup compression rings, are installed beneath compression rings. They serve primarily to remove excess oil from the liner surface and to stop any gas leakage that escapes the top compression ring further down. In most wiper rings, the taper angle face is located toward the bottom so that it can wipe against the crankshaft during piston movement.

Oil consumption increases if the wiper ring tapered angle needs to be installed correctly near the compression ring. The wiper ring is used when excess oil is being wiped towards the combustion chamber.

Oil Control/Scrapper Rings

Lubricating oil passes up and down the cylinder walls through oil control rings. Rings like these also spread the oil evenly along the liner’s circumference.

Cylinder walls are splashed with oil, and oil is scraped off the cylinder walls by these rings and returned to the crankcase.

The cylinder face and ring face are sealed together, so the oil cannot pass through.

The oil ring has holes or slots drilled into its radial center, which allow excess oil to flow into the reservoir.

One-piece or two-piece oil rings are available. By having chamfered edges on either the outer sides or facing the combustion chamber, rings can increase contact pressure with the liner surface to reduce oil consumption through more efficient oil scraping.

The coil spring on a two-piece oil control ring acts around the entire circumference of the ring to maintain pressure and contact, as well as a cast iron or profiled steel ring.

Four Functions of Piston Rings

There are four functions of piston rings:

- Seal for Combustion Gas

Its purpose is to maintain airtightness inside the cylinder while the piston is in it.

It keeps combustion gases from leaking into the gap created when pistons and cylinders explode.

Leaking combustion gas would result in reduced power and increased fuel consumption, which is detrimental to the environment and the economy.

- Control Lubricating Oil (Engine Oil)

It is one of the piston rings’ functions to ensure a minimum layer of lubricating oil to protect against burns.

In an engine’s cylinder, the piston ring encounters high combustion gas temperatures each time it moves, and the piston must also travel back and forth thousands of times a minute.

By keeping the cylinder wall lubricating oil layer below the minimum required, piston rings and cylinders will not burn, and excess lubricating oil won’t enter the combustion chamber.

- Heat Conduction Function

The cylinder heats up when a piston is pushed out of its cylinder.

A piston explodes at approximately 300 degrees centigrade when gas explodes inside it. Heat must be released from the interior of the piston to avoid damaging the engine. Piston rings assist in this process.

- Piston Attitude Support

Piston rings prevent intense contact between the piston and the cylinder wall.

During piston movement, a piston at an angle can contact several places, leading to engine damage. To travel smoothly, the piston ring supports the piston.

Final Words

Now you know that primarily, piston rings are used to seal the combustion chambers in diesel engines. You also know about the variety of uses these rings have. So now it’s your turn to put this information to good use. Feel free to reach out if you still want to know something else about them.

B.E (Mechanical) Mumbai, MBA – ISB, Hyderabad (2011)

Managing Director at Atrac Engineering Co (manufacturers and exporters of aftermarket engine parts)

Member of EO Navi Mumbai.

Hobbies include avid fitness enthusiast – crossfit, golf and trekking.