Hydraulics is a term used for the study of liquids and how they function. In engineering, the term hydraulic systems refer to those that work by using pressurized fluid to power an engine. These systems put pressure on a small amount of fluid to generate large amounts of power. The discovery of the use of hydraulics has enabled us to accomplish significant work, such as lifting heavy loads and turning huge shafts with minimum input through a mechanical linkage.

Hydraulic power systems are more flexible than mechanical and electrical systems and produce more power than systems of equal size. They also provide rapid and accurate responses to controls. As a result, hydraulic power systems are extensively used in modern aircraft, automobiles, heavy industrial machinery, and many kinds of machine tools. In this article, we will particularly discuss the hydraulic system in a tractor.

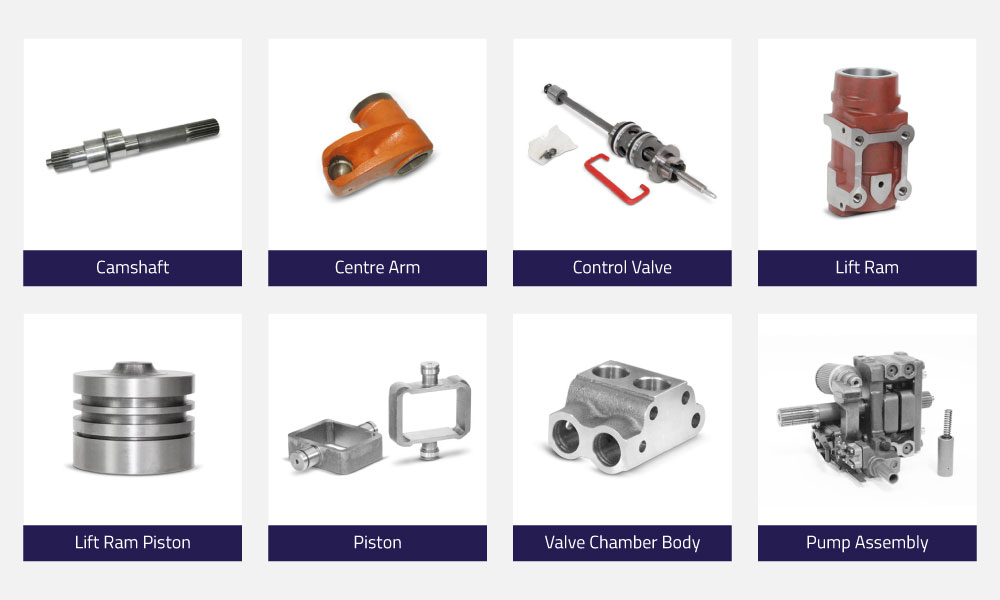

Tractor hydraulic parts

- Hydraulic pump

- Hydraulic cylinder

- Piston

- Hydraulic tank

- Control valve

- Safety valve

- Hosepipe and fittings

- Lifting arms

- Camshaft

- Centre arm

The hydraulic pump draws up oil from the oil reservoir and sends it to the control valve under high pressure. From there, the oil goes to the hydraulic cylinder to operate the piston which in turn raises the lifting arms. The hydraulic pump is operated by suitable gears that are connected with the engine.

There are two types of arrangements for storing hydraulic oil:

- There is a common oil reservoir for hydraulic system and the transmission system in some tractors

- There is a special tank for hydraulic oil that is separate from the transmission chamber

Hydraulic pump:They are of several types, such as gear pump, plunger pump, vane pump, and screw pump. Gear pumps are widely used in tractors because they can flow a large amount of oil in comparison to a plunger pump. The oil pressure in the pump varies from 150 to 200 kg/cm2.

Hydraulic cylinder: It is a bigger cylinder fitted with a piston and a connecting rod, also called a ram cylinder. The piston moves in the hydraulic cylinder and causes reciprocating motion in the cylinder. It is the connecting rod that transmits power from the piston to the lifting arms. Although the lifting arm is raised by hydraulic pressure, it is lowered by its weight.

Hydraulic tank: It is used for storing hydraulic oil. In some tractors, the transmission chamber itself works as a hydraulic tank and the same oil is used for both transmission and hydraulic systems.

Control valve: It controls the movement of hydraulic oil to have desired direction, magnitude, and speed for lifting.

Oil filter: It is a small filter located at a convenient position in the passage of the oil.

Challenges that hydraulic parts have to endure

Agriculture and allied activities are constantly evolving. With recent advancements in science, agro-based industries are coming up in terrains and locations that were previously unexplored. The topography of these areas has to go through various changes to meet land use standards. Heavy machinery, such as trucks and tractors, has to work in harsh climatic conditions, within a set duration to bring the sites up to speed.

These machines use heavy-duty engines as they are subject to a lot of strenuous work. The resulting friction within the engine has to be reduced to maintain performance and increase life. For engines to become more robust and advanced, hydraulic technology must be at the forefront, as these components are the ones that endure the load in driving the crankshafts and must generate a consistently high power delivery.

At Atrac, we take into account what the future holds for the agriculture and allied industry and constantly endeavor to keep up with those needs. With our state-of-the-art manufacturing and testing facility, we produce high-quality hydraulic parts such as camshafts, control arms, control valves, lift rams, and pistons, that not only meet industry standards but also meet Original Equipment Manufacturer (OEM) specifications. These parts have proved reliable on the field and have stood true to our promise of quality and assurance.

To know more, visit www.atracparts.com.

B.E (Mechanical) Mumbai, MBA – ISB, Hyderabad (2011)

Managing Director at Atrac Engineering Co (manufacturers and exporters of aftermarket engine parts)

Member of EO Navi Mumbai.

Hobbies include avid fitness enthusiast – crossfit, golf and trekking.

One thought on “Hydraulic Parts of a Tractor and Their Functions”

Comments are closed.