Have you ever looked at vehicles pass by and wondered how a small amount of liquid fuel can run such massive automobiles? Is it not remarkable that diesel engines power heavy vehicles like trucks, trains, and tractors? Well, this is possible because of a rather simple but amazing scientific principle that was established by Rudolf Diesel in 1893. In a diesel engine, the air is compressed to a sufficiently high temperature to ignite the diesel fuel injected into the cylinder. The resulting combustion and expansion get the piston moving. Hence, the chemical energy stored in the fuel converts into mechanical energy and powers vehicles.

Parts of a diesel engine

An engine block is the main structure that supports all the other engine parts. These are the components that form the core of the working of a diesel engine:

- Sleeved cylinder liners

- Pistons with attached piston rings

- Engine Valves — intake and exhaust valves

How does a diesel engine work?

Most diesel engines work on a four-stroke cycle. A stroke refers to the full travel of the piston along the cylinder, in either direction and it completes four separate strokes while turning the crankshafts. Air is injected into the chamber of the cylinder at regular intervals through the inlet valve. The piston within the liner moves up and down compressing air above it. When the piston reaches the effective end of its induction stroke, the inlet valve closes. The power from the other pistons and the momentum of the flywheel, helps the piston travel to the top of the cylinder, compressing the air into about a twentieth of its original volume. This compression generates heat that fires the fuel/air mixture, causing it to burn and expand forcing the piston downwards, turning the crankshaft. As the piston moves up the cylinder, the exhaust valve opens and allows the burned and expanded gases to travel down the exhaust pipe. At the end of the exhaust stroke, the cylinder is ready for a fresh charge of air.

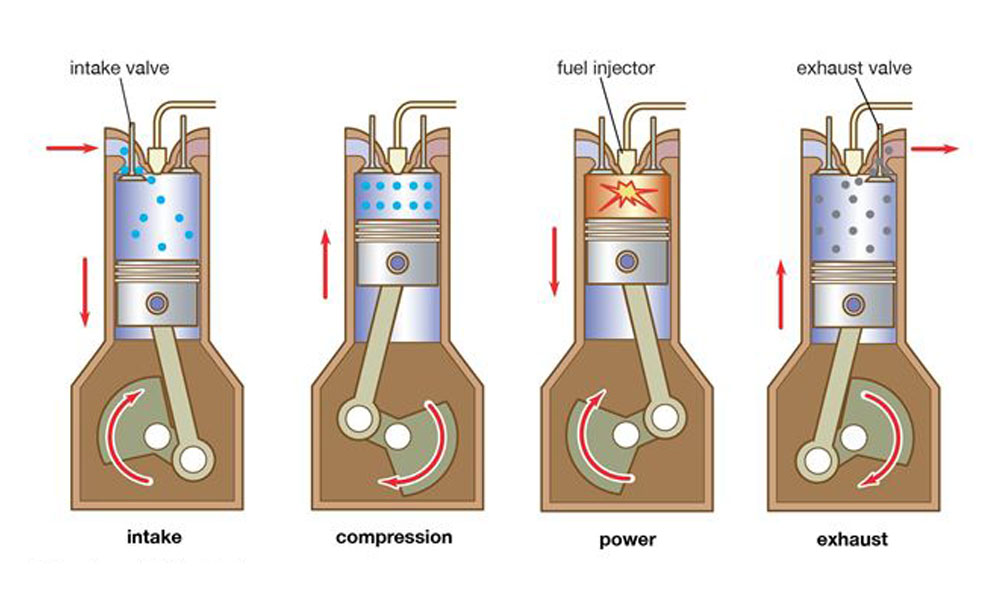

This entire process can be categorized into four steps:

Induction —As the piston begins to move down the bore, the inlet valve opens and air is injected into the chamber.

Compression —The inlet valve closes at the bottom of the stroke. The piston rises to compress the air.

Ignition — Fuel is exposed to the heat of the compressed air resulting in combustion and expansion that forces the piston down.

Exhaust —On the piston’s upward travel, the exhaust valve opens, and burned gas is expelled.

Engine construction

Diesel engine parts have to be made much stronger than their petrol engine equivalents because of the much higher loads involved. The walls of a diesel engine block are much thicker than a petrol engine block and have more bracing webs to provide extra strength and absorb stress. Apart from being stronger, the heavy-duty block can also reduce noise more effectively.

Pistons, connecting rods, crankshafts, and bearing caps have to be made strongerthan their petrol engine counterparts.

Diesel engines are always pitted against petrol engines. Has that conversation on petrol vehicles vs diesel vehicles confounded you? Here is a simple explanation of how the two are different.

The main advantage of diesel engines over petrol engines is their lower running cost. This is because of the typically low price of diesel fuel and its high compression ratio — the volume of the cylinder when the piston is at the bottom of its stroke divided by the volume of the cylinder when the piston is at the top. A typical compression ratio for a diesel engine is 20:1, compared with 9:1 for a petrol engine. However, the fuel price varies from one region to another, so the advantage of running a diesel car will be slightly reduced if you live in an area with high-priced diesel fuel.

It isn’t just about deciding between petrol and diesel engines, but ensuring that you choose the right parts for your engine based on the utility of your vehicle. It is important to verify the authenticity of the engine parts you buy and check if they qualify OEM specifications. This is why major automobile manufacturing brands partner only with those that deploy rigorous quality testing measures. At Atrac, we are committed to ensuring precision, dimensional accuracy, and quality. For decades, we have been partnering with customers in 60 locations across four continents.

To know more, visit www.atracparts.com.

B.E (Mechanical) Mumbai, MBA – ISB, Hyderabad (2011)

Managing Director at Atrac Engineering Co (manufacturers and exporters of aftermarket engine parts)

Member of EO Navi Mumbai.

Hobbies include avid fitness enthusiast – crossfit, golf and trekking.

203 thoughts on “How do diesel engines work?”

Comments are closed.